More than just a technical upgrade, dynamic production represents a paradigm shift. This new border enables the inclusion of cutting-edge technologies to create an extremely intelligent environment where connected producing plants go beyond the boundaries of conventional technology. One of the powerful tools manufacturers are using is artificial intelligence, electric twins, and robotics, which are among the powerful tools they use to build dynamic, smart systems that not only conduct tasks but also understand, make decisions, and develop in real-time.

This type of dynamic technique can increase a manufacturer’s productivity, effectiveness, and innovation. Beyond the factory, it also has the potential to bring about society-wide benefits, such as encouraging local economic growth, promoting more appealing and available employment opportunities, and promoting a sustainability agenda.

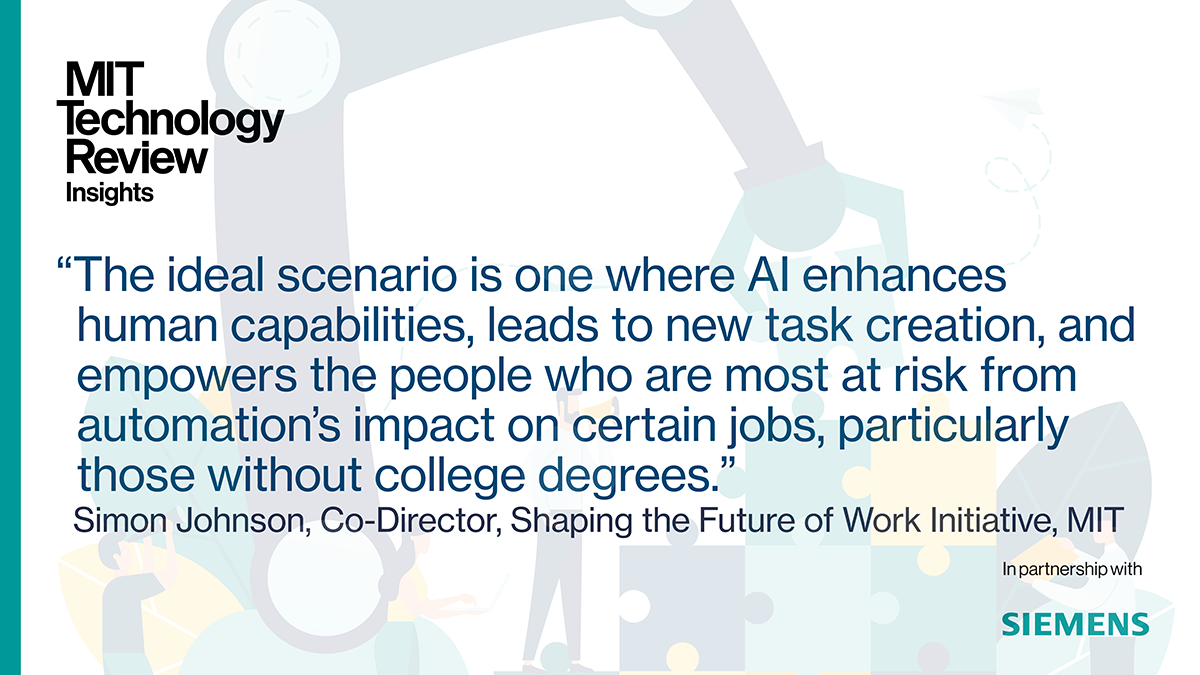

In addition to attracting and retaining skill, adaptable production may help producers overcome some of their biggest challenges as attempts to revive and upgrade nearby manufacturing grow in areas around the world, including North America and Europe. In a 2024 US-based study, nearly 60 % of companies cited this as their major problem. Highly automated, technologically-led dynamic production techniques hold new guarantee for attracting skill for roles that are safer, less monotonous, and better paid. According to Simon Johnson, co-director of MIT’s Shaping the Future of Work Initiative,” the ideal situation is one where AI enhances people capabilities, leads to new work development, and empowers the people who are most at risk from automation’s impact on some jobs, especially those without college degrees.”

Second, through process and source optimization and a better understanding of data, companies can better address complex sustainability issues because of the digitalization of manufacturing, which is at the heart of dynamic production technologies. By integrating these cutting-edge systems, Jelena Mitic, mind of technologies for the Future of Automation at Siemens, claims that we can have a more accurate view of the entire creation process and product lifecycle. This will give you a much faster and more effective way to improve businesses and make sure that all the important safety and sustainability standards are met during quality control.

Download the full statement here.

This writing was done by MIT Technology Review’s Insights, its division for practice writing. It was not edited by the journal team of MIT Technology Review.

This text was created, written, and edited wholly by mortal authors, editors, experts, and illustrators. This includes gathering info for research and writing them. AI tools that might have been employed were restricted to second-party production processes that underwent complete human testing.